Continuous CUI Monitoring

–

Non-Intrusive and Wireless

With the I-tiQ sensor family from Senergetics, corrosion under insulation (CUI) is detected early – before it causes costly damage.

The ATEX-certified I-tiQ sensors continuously monitor moisture, temperature, and leaks during operation – without shutdowns or insulation removal.

Optional Probe Sensors record the operating temperature directly at the equipment surface and correlate it with the insulation surface temperature. This enhances response speed and accuracy in the AI-supported analysis.

From Spot Checks to Real-Time Transparency

Traditional inspections provide only snapshots and require significant effort.

The I-tiQ system records temperature data every minute, creating a dense network of information that identifies changes early – without exposing any operational or safety-critical data.

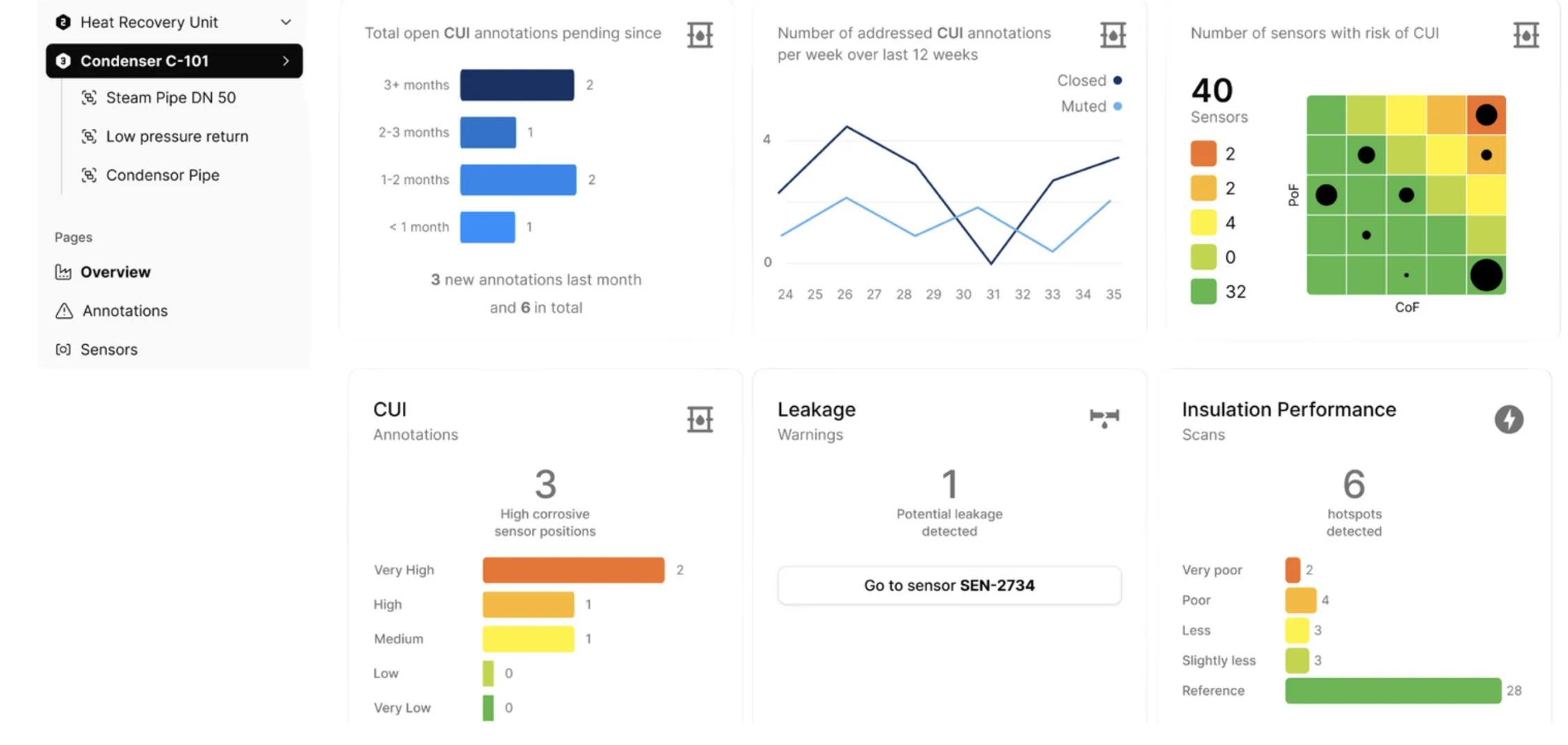

In the SentreQ cloud, all readings are processed by AI within the Sen-AID dashboard.

The dashboard is designed for everyday use – intuitive, visual, and easy to understand for your in-house teams. No specialized training required. Clear risk levels and actionable recommendations make your asset condition transparent and easy to manage at any time.

How It Works

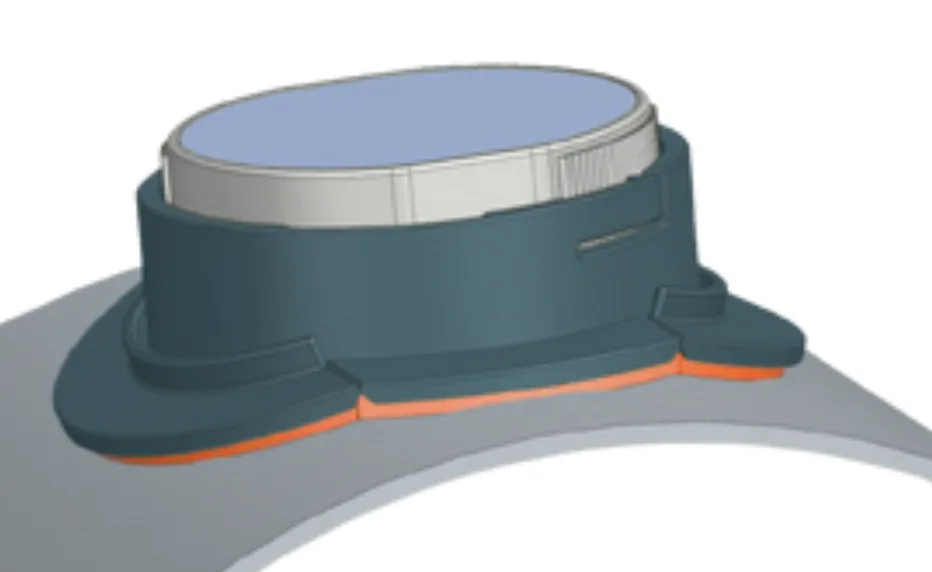

The sensor mounts, including compact sensors (diameter approx. 5 cm / 2 in), are applied manually or by drone to the metal cladding. For piping, optional tension bands can be added for extra hold.

The maximum spacing between sensors should not exceed 10 m / 33 ft. For reliable CUI detection, a spacing of 1–3 m / 3–10 ft is recommended. The cladding remains fully intact – no drilling, screws, or penetrations are required. Vapor barriers in cold insulation systems remain completely unaffected during installation and operation.

The wireless sensors form a mesh network and transmit their data to the gateway, which then forwards all collected data to the SentreQ cloud. The gateway simply requires a standard 220 V power connection – nothing more. Each sensor operates on a 10-year battery life.

The Probe Sensor complements surface data by adding the actual process temperature.

Direct comparison of process and surface temperatures improves the interpretation of moisture and heat flow, making CUI and leak alerts faster and more reliable.

Result: Permanent AI-driven monitoring, early and reliable warnings of CUI risks, targeted maintenance, optimized use of skilled labor, extended asset lifetime, and a lower risk of CUI-related leaks or failures – all without opening insulation or installing scaffolding.

Key Advantages

- Installed during live operation – no shutdowns required

- Continuous CUI detection and early warning of insulation degradation

- Targeted repairs instead of large-scale insulation removal and inspection

- Significant cost reduction and improved safety compared with traditional CUI testing

- Proven field accuracy > 95% (references include KAEFER, Sitech, and Unilever)

- Scalable from pilot projects to full-site CUI coverage

Dipl.-Ing. Stephan-F. Reichinger

TIPCHECK Expert Level 4

FROSIO Insulation Inspector Level 3

Proven in the Field

KAEFER Field Test (2024):

100% detection accuracy in a live test loop with alternating temperatures (70–120 °C / 160–250 °F).

Early- and late-stage corrosion was precisely located, outperforming seven other CUI detection technologies.

Sitech Chemelot (2025):

Combined monitoring of corrosion risk and insulation performance on pipelines operating at 140 °C / 284 °F.

Result: No undetected CUI, verified on-site; insulation deficiencies identified, repaired, and unnecessary heat losses eliminated.

Unilever / Ben & Jerry’s (2024):

Reliable detection on –40 °C / –40 °F ammonia pipelines with 97% accuracy – 100% of defective sections identified!

Other Services

- Energy Audits according to the EiiF TIPCHECK standard

- Construction Supervision & Quality Inspection of Industrial Insulation – independent supervision and random inspection of insulation works to verify compliance with specifications, standards, and best practices

- Specification Review and Updates for modern and compliant insulation guidelines

- Independent Expert Assessments and Reports

- Employee training programs for sustainable energy efficiency

Request Expert Advice for Non-Intrusive CUI Detection

Discover how I-tiQ and Probe Sensors improve safety, reduce maintenance costs, and prevent corrosion under insulation.