EiiF TIPCHECK Audit

Inspect Technical Insulation.

Save Energy.

Enhance Safety.

As a certified EiiF TIPCHECK Expert Level 4, we analyze your industrial facilities according to European standards.

We identify where energy losses occur, show you how to reduce operating costs, lower CO₂ emissions, and prevent corrosion under insulation (CUI).

What is an EiiF TIPCHECK Audit?

TIPCHECK stands for Technical Insulation Performance Check and is a Europe-wide recognized audit standard developed by the

European Industrial Insulation Foundation (EiiF).

It identifies energy-saving opportunities caused by insufficient or damaged insulation in industrial plants.

The results form the basis for investment decisions and can be seamlessly integrated into energy management systems (ISO 50001).

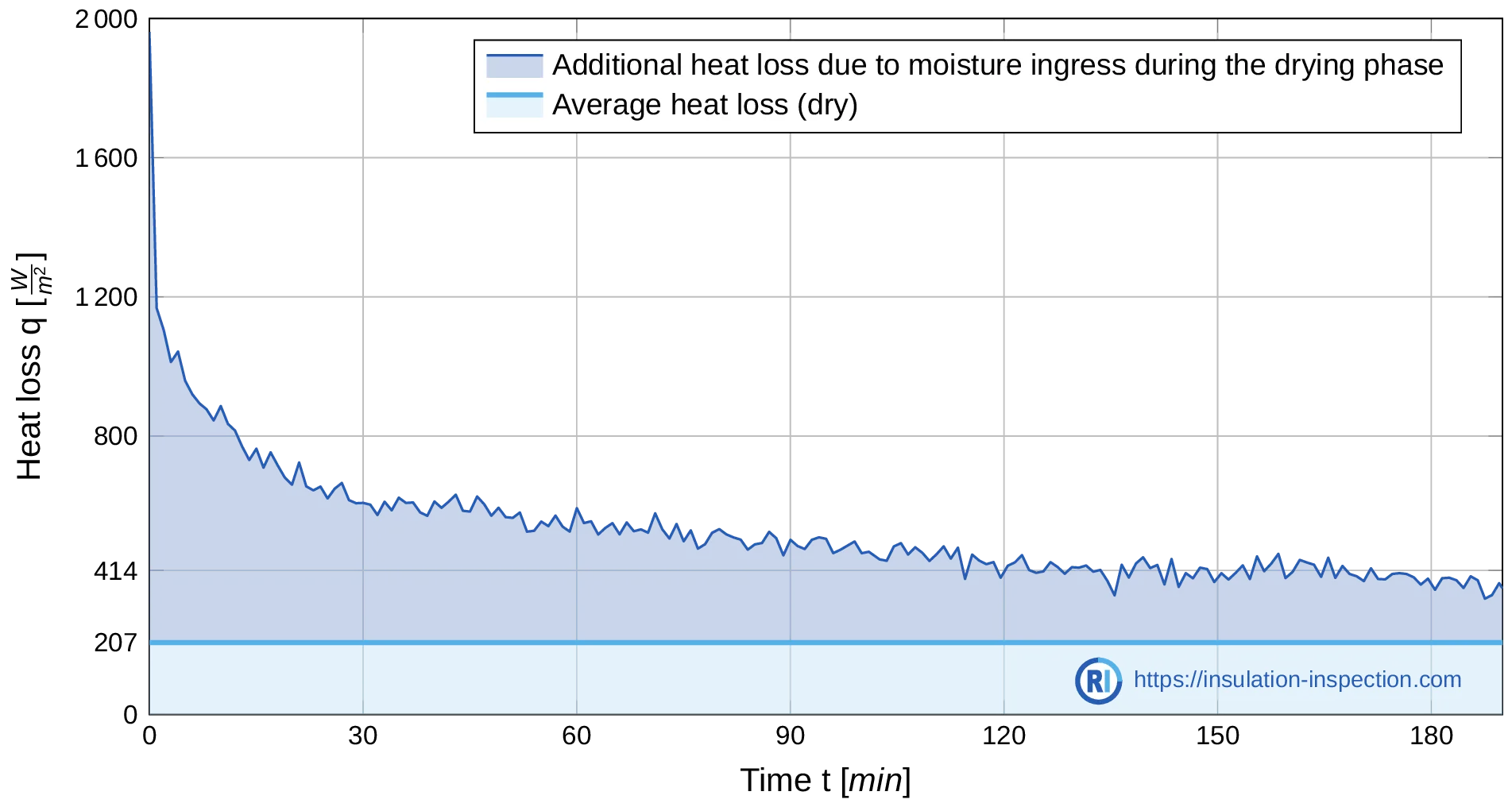

Moisture dramatically increases heat losses – even hours later

Even two hours after a short moisture ingress, heat loss can still be about twice as high as in a dry condition. At the start – or during ongoing rainfall – it can even rise to eight times the normal level. As long as residual moisture remains in the insulation material, valuable heat energy is unnecessarily lost.

The reason: moisture conducts heat much better than air. In intact open-cell insulation materials, the space between the fibers is normally filled with air. Moisture can enter, for example, through damaged and unrepaired cladding, improperly installed systems, or leaks in insulated equipment.

In the diagram below, the heat loss in a dry condition is 207 W/m² (light blue line and area). For about one minute, approximately one liter of water was introduced through damage in the sheet metal cladding. One liter corresponds to a rainfall amount of one millimeter per square meter. Immediately afterwards, a new measurement was taken. It started at about eight times the normal value (around 1,800 W/m², dark blue line and area) and, even after two hours, remained above twice the dry-system value (414 W/m²).

The exact values depend on boundary conditions such as equipment size, operating temperature, insulation thickness, and the age and quality of the insulation material. Nevertheless, the results clearly show the impact that properly maintained insulation can have on reducing energy losses in an industrial facility.

🌍 Others plant trees – we stop CO₂ at the source

Instead of offsetting emissions later by planting trees, we show you directly at your industrial site where and why unnecessary heat losses occur and how to prevent them.

As a certified EiiF TIPCHECK Expert Level 4 and FROSIO Insulation Inspector Level 3, we provide a solid decision-making basis for you,

following European standards (EN 16247, ISO 50002, EN 17956).

Our audits typically deliver a fast payback and help you sustainably reduce operating costs and CO₂ emissions.

Dipl.-Ing. Stephan-F. Reichinger

15+ years of experience

FROSIO Level 3

TIPCHECK Expert Level 4

Our Proven Results

Waste Incineration Plant:

Savings: €70,000/year | CO₂ Reduction: 420 t/year | Payback: < 12 months

💡 Audit cost paid back in: < 1 month

➜ 30% energy losses eliminated on piping and tanks, CUI risks minimized.

🌳 Equals the annual CO₂ absorption of approx. 50 soccer fields of forest.

Refinery:

Savings: €115,000/year | CO₂ Reduction: 380 t/year | Payback: < 2 years

💡 Audit cost paid back in: < 2 weeks

➜ 95% energy losses eliminated on a single tank.

🌳 Equals the annual CO₂ absorption of approx. 46 soccer fields of forest.

Manufacturing Facility:

Savings: €20,000/year | CO₂ Reduction: 70 t/year | Payback: < 2 years

💡 Audit cost paid back in: < 3 months

➜ 90% heat losses identified and improved through optimized insulation.

🌳 Equals the annual CO₂ absorption of approx. 8 soccer fields of forest.

Examples from the European Industrial Insulation Foundation (EiiF)

Refinery – Oil Tank Roof:

Savings: €185,000/year | CO₂ Reduction: 1,500 t/year | Payback: < 2.5 years

➜ Insulating previously uninsulated tank roofs delivered massive energy savings.

🌳 Equals the annual CO₂ absorption of approx. 180 soccer fields of forest.

Refinery – Single Valve:

Savings: €3,200/year | CO₂ Reduction: 51 t/year | Payback: < 1 year

➜ Even small uninsulated components can cause significant energy losses – quick fixes pay off.

🌳 Equals the annual CO₂ absorption of approx. 6 soccer fields of forest.

Source: EiiF TIPCHECK Case Studies

How the Process Works

1. Initial Contact

Send us your inquiry along with a few photos of your facility (piping, tanks, valves, etc.). This helps us get a first impression and address your needs effectively.

2. Free Online Consultation

In a 30–45-minute Microsoft Teams meeting, we identify initial savings opportunities – completely free and without obligation. Afterwards, you’ll receive a tailored offer for an EiiF TIPCHECK Audit.

3. On-Site Audit & Action Plan

Once commissioned, we conduct an audit following the EiiF TIPCHECK standard, determine your savings potential, and develop a clear action plan. Results are discussed with you either online via Teams or in person on site.

Additionally, the findings can be seamlessly integrated into your energy management system (e.g., ISO 50001) as a foundation for continuous efficiency improvements and reporting.

4. Optional Support & Implementation

Following the audit, we can optionally support you further: revising your insulation specifications, providing site supervision, or conducting quality checks with your insulation contractor – tailored to your needs.

Other Services

- Non-Intrusive Long-Term CUI Monitoring – continuous, wireless measurement of moisture and temperature trends for early warning of corrosion risks and leaks

- Construction Supervision & Quality Inspection of Industrial Insulation – independent supervision and random inspection of insulation works to verify compliance with specifications, standards, and best practices

- Specification Review and Updates for modern and compliant insulation guidelines

- Independent Expert Assessments and Reports

- Employee training programs for sustainable energy efficiency

Have Your Facility Insulation Checked Now

Independent, risk-free, and in compliance with recognized TIPCHECK standards.

🌱 And don’t worry – a TIPCHECK won’t stop you from planting a few trees as well. We’ll handle rapid CO₂ reduction in your facility – nature benefits from both!